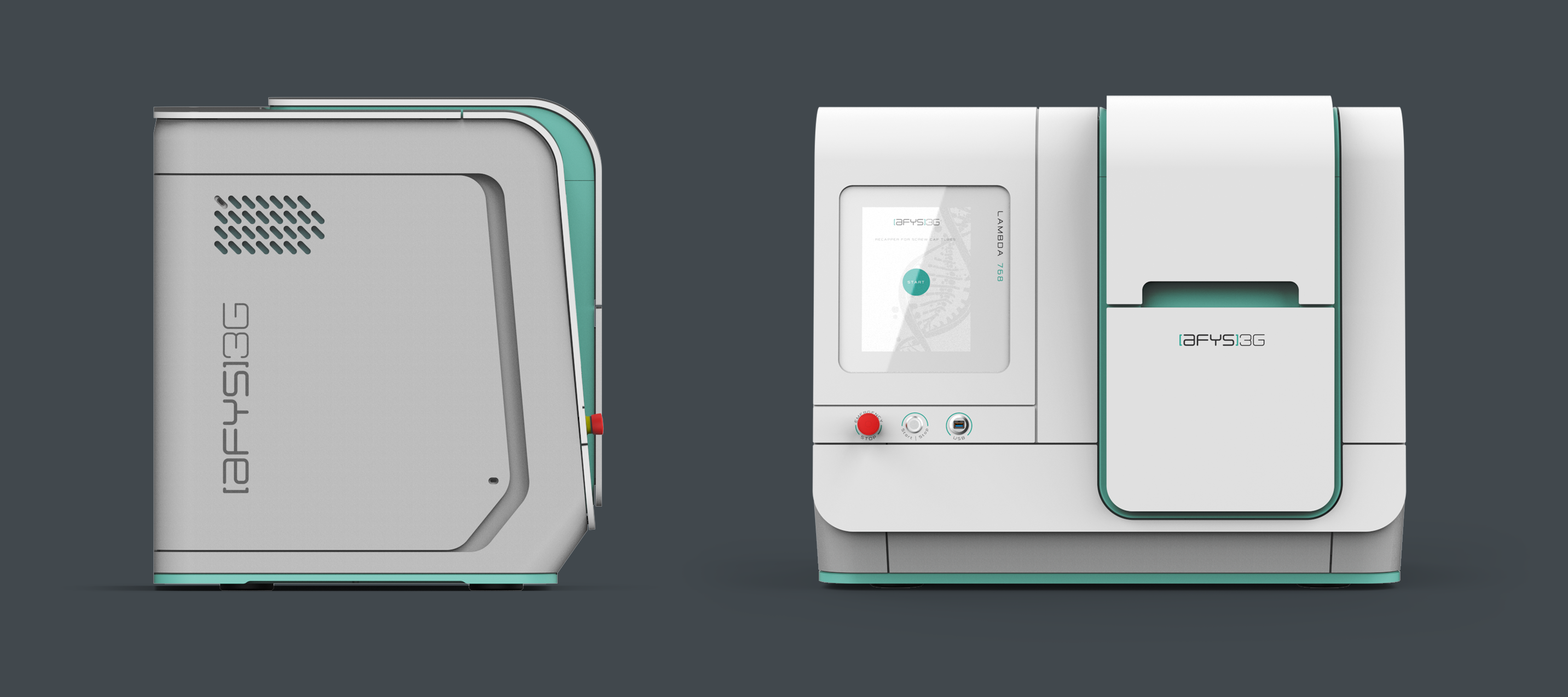

Lambda768 Automated laser marker

AFYS3G is a skilled manufacturer of lab equipment focused on the Life Sciences Industry. They offer high quality solutions for a number of applications such as sample handling, sample management, laboratory services and liquid handling.

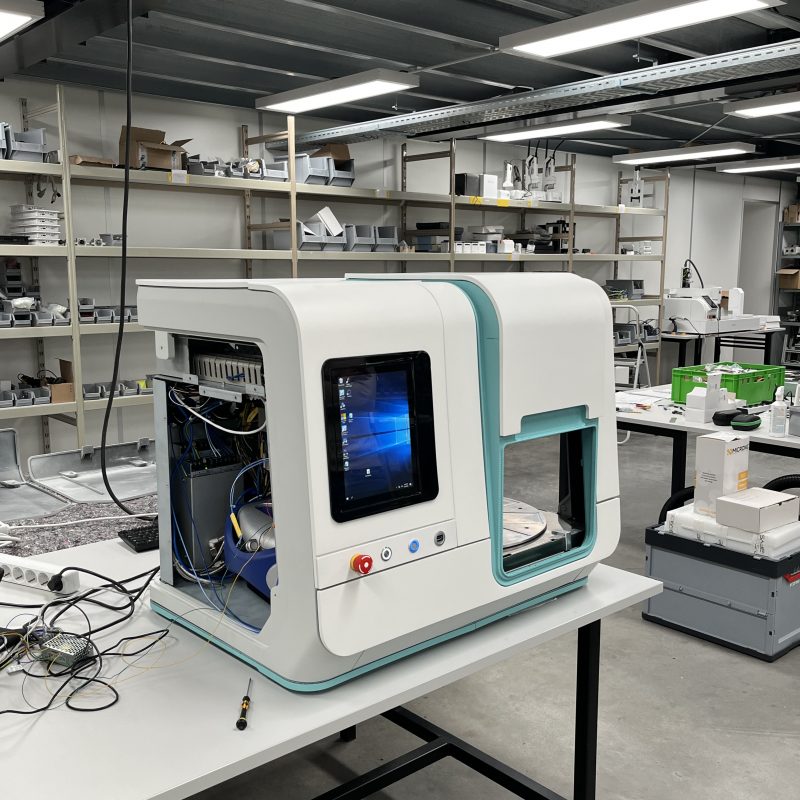

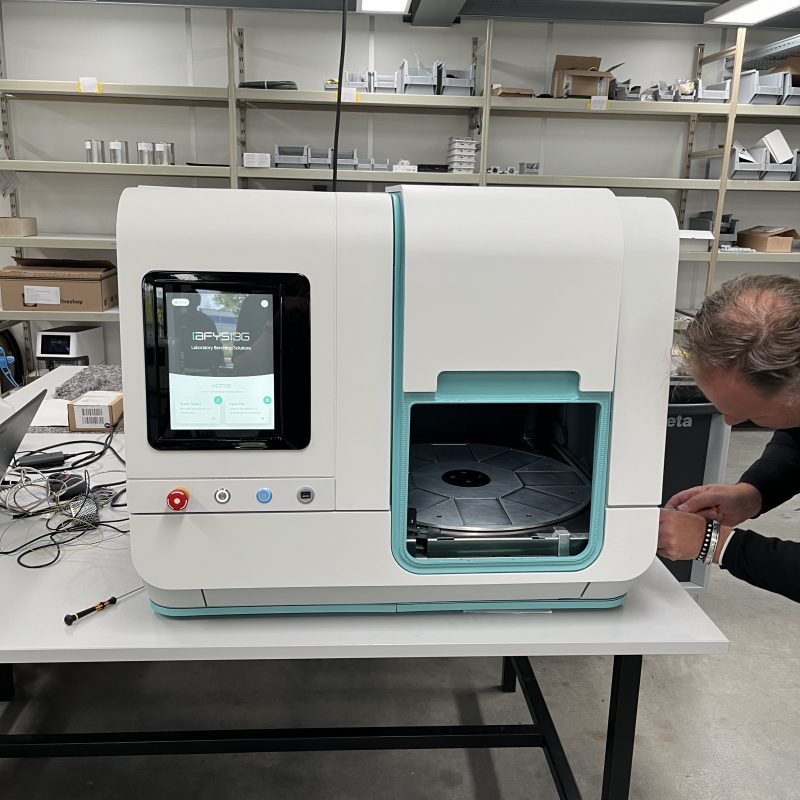

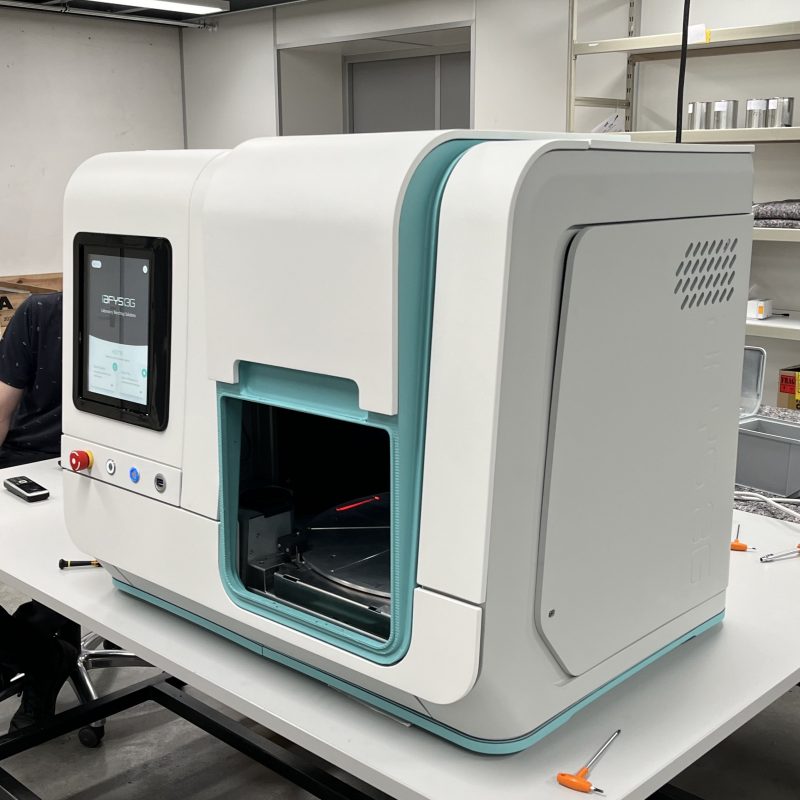

AFYS3G engaged Helder-ID to design an innovative line of lab equipment tailored for high-throughput environments. We crafted a cohesive design approach for this range, focusing on functionality and adaptability through 3D-printed housing components. The Lambda768, an automated laser marking system for tube racks, is the first in this new series, embodying AFYS3G’s standards for precision and usability.

Industry

Life Sciences

Professional

Services

Product design

Engineering

Prototyping

Design for manufacturing

Unified design

AFYS3G envisioned a cohesive, versatile design language for its new lab equipment range, prioritizing a clean and clinical aesthetic, compatible with typical lab spaces. Our comprehensive approach allows each device in the series, beginning with the Lambda768, to maintain a unified look, reinforcing both AFYS3G’s brand identity and the practical needs of modern laboratories.

Clear and efficient interaction

The Lambda768, the first-of-its-kind automated laser marker, is designed to replace manual or automated tube labeling, reducing errors. With engravings applied to a non-transparent area, labels remain readable regardless of sample type or color.

The streamlined housing design promotes clear, efficient user interaction, making sample identification both faster and more reliable.

Local production

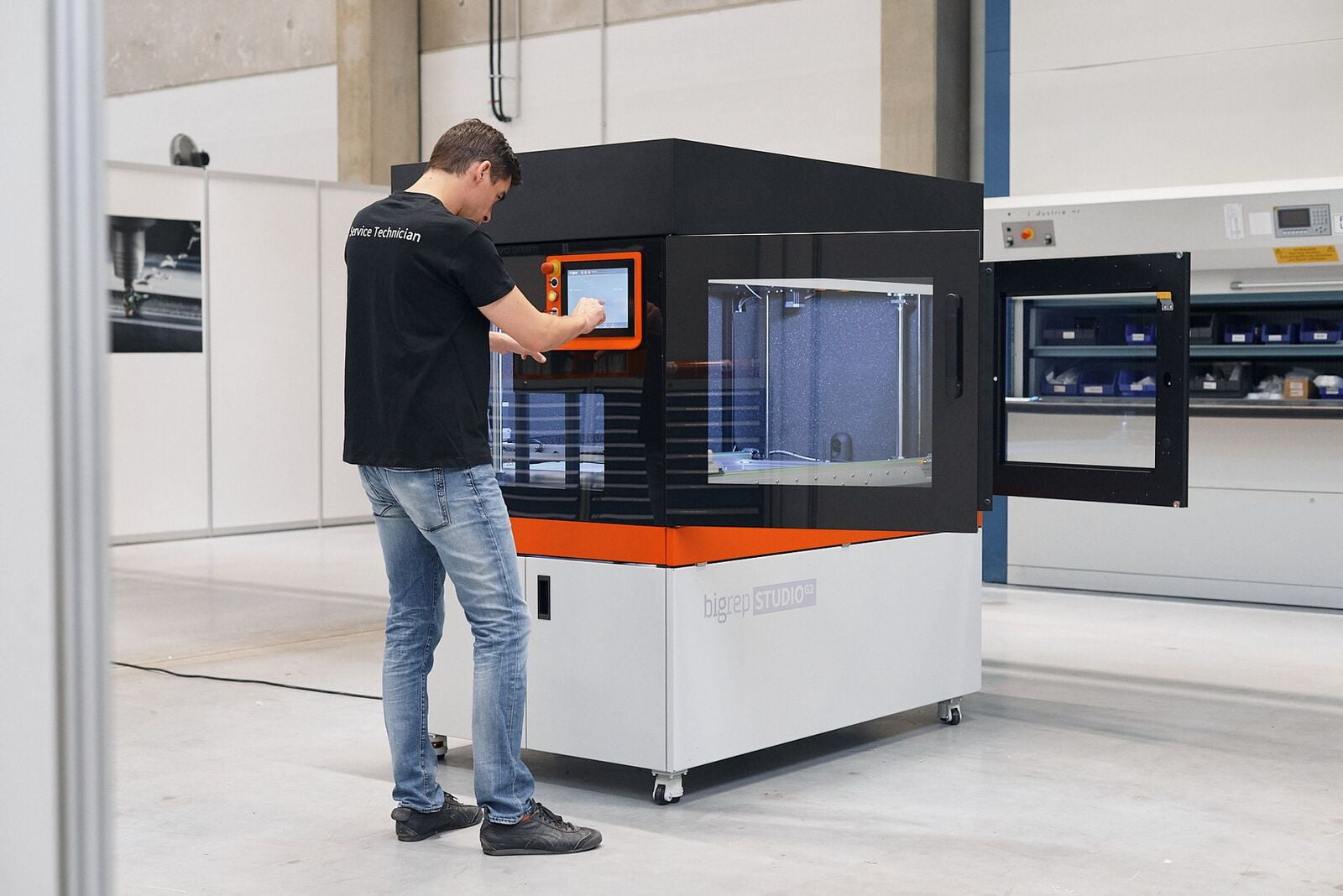

The housing for the Lambda768 was designed specifically for low-volume production using AFYS3G’s BigRep Studio 3D printer. This approach allowed for a precise, customizable build, with clever segmentation of the housing components to ensure ease of assembly and cost-effectiveness. Each part of the design was optimized for the 3D printing process, supporting AFYS3G’s goals of flexibility and functionality in a streamlined production workflow.