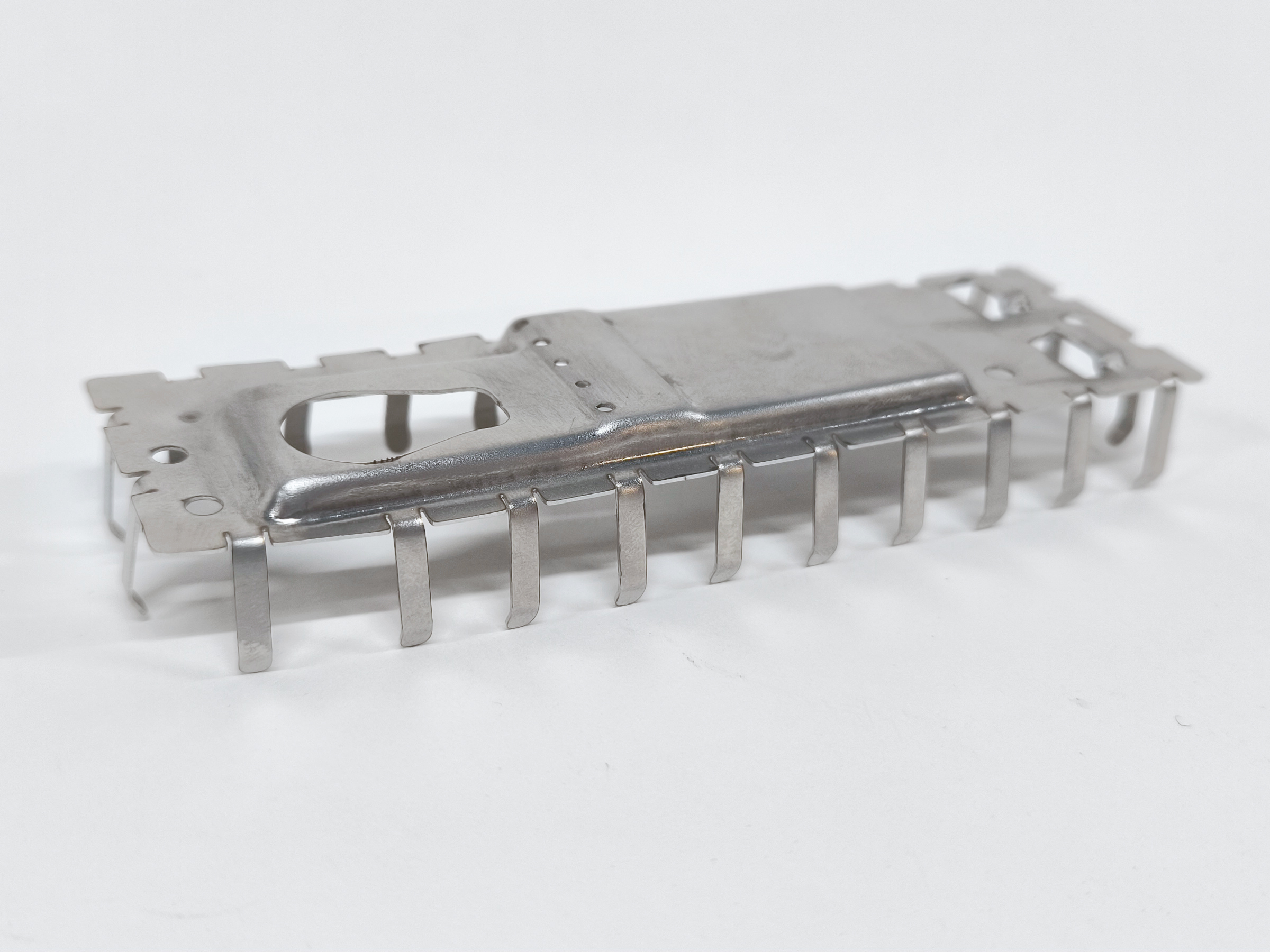

We handle sourcing, production, and quality control to bring products to market.

At Helder Products, we specialize in transforming innovative designs into tangible, high-quality products. From sourcing moulds to overseeing full-scale production, we handle the entire process so that our clients can focus on growing their business. Our global network of suppliers, primarily based in the Netherlands and China, and our expertise in prototyping, testing, and manufacturing ensure that every project is executed with precision and efficiency.

Source

Sourcing and supplier management

Finding the right partners is critical for successful production. We work closely with trusted suppliers, in Europe as well as in Asia, to source high-quality moulds and components for your project. We’ve built relationships that already last for over 30 years and our expertise ensures that we can negotiate the best quality at competitive prices, while keeping lead times efficient. Our local sales manager in China also makes sure we identify the best suppliers and maintain strong partnerships to consistently meet our production needs.

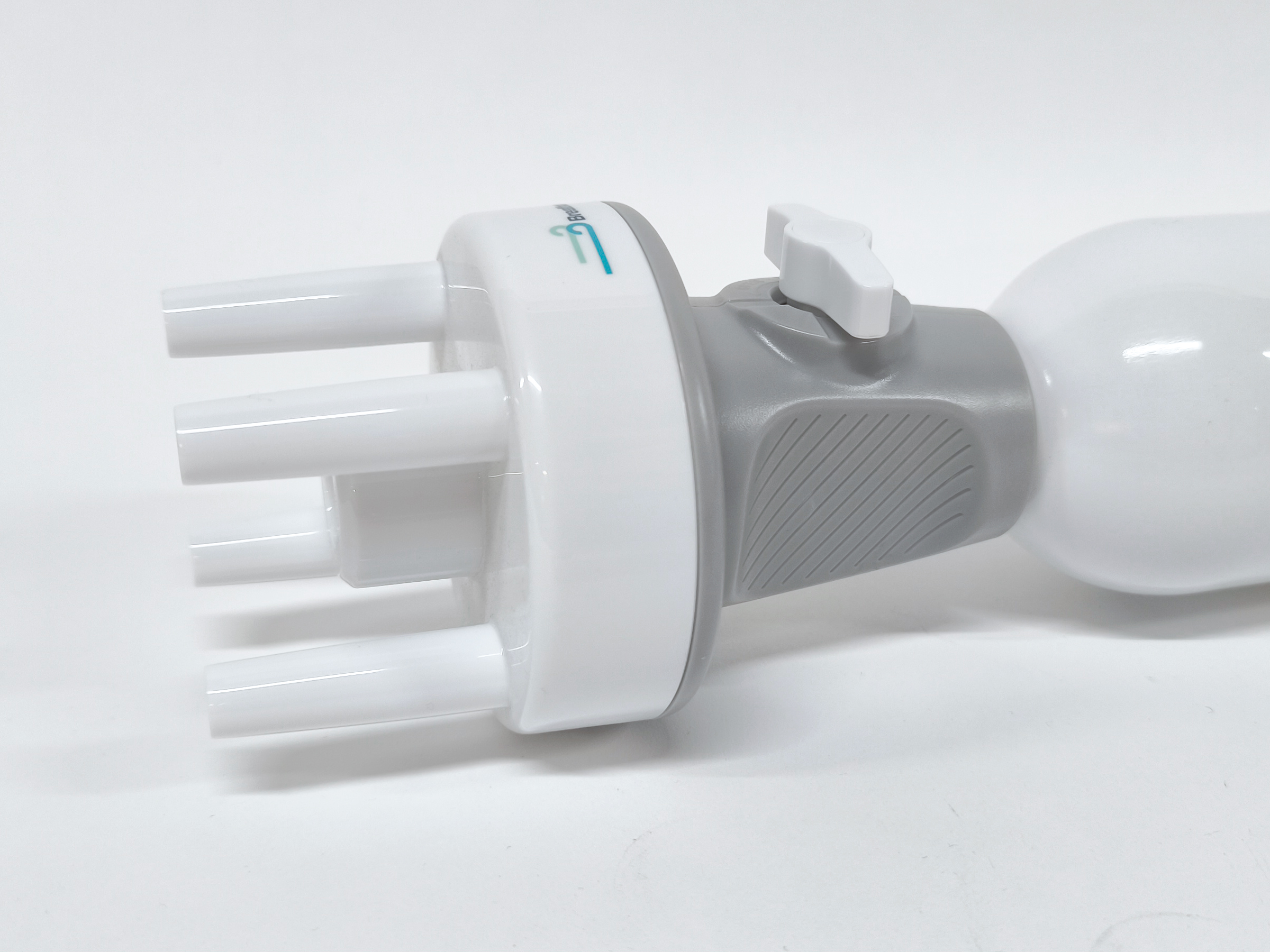

For example, in the development of the Fooom Soap Dispensers, we managed the entire supply chain—sourcing moulds from China while starting production at a local Dutch injection molding facility to optimize logistics and costs.

Experience

Prototyping and testing

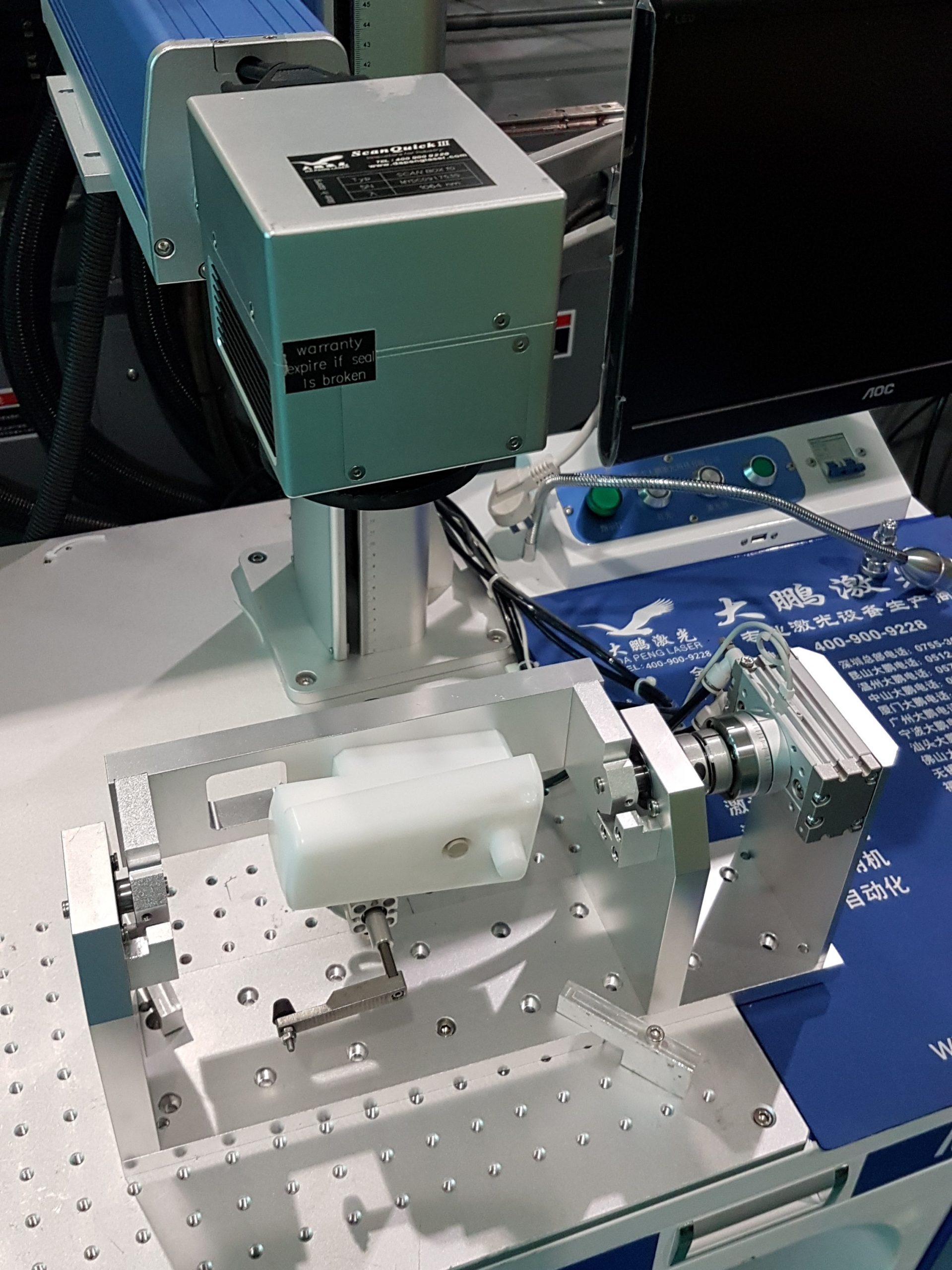

We offer a wide array of prototyping services, including 3D printing and CNC machining. This phase allows to iterate and refine the designs, ensuring they meet functional and aesthetic requirements before moving to mass production.

Helder-ID’s design projects, like the CGM Wearable, benefited from this approach. Prototypes were not only designed for user experience but also tested rigorously to meet CE compliance, allowing the device to move seamlessly into clinical trials. In another instance, for the StreetSense Sensor Pod, we developed prototypes that were tested under real-world conditions like heavy traffic and extreme weather, ensuring the product was ready for market.

Manage

Production coordination

We handle the full-scale production process, whether manufacturing in Asia or in Europe. With our comprehensive oversight, we ensure that the final product matches our clients’ quality standards while keeping to budget and deadlines.

For example we managed the production for projects like the Philips LatteGo milkfrother, ensuring smooth sailing from design to full production.

Finalize

Quality assurance and delivery

Quality is our top priority, from the first prototype to the final product. We oversee rigorous quality checks throughout the production process to ensure that every product meets the necessary standards. Once production is complete, we ensure timely delivery, getting a product to market when our client needs it.